Custom Aluminium Fabrication Projects: From Client Design to Finished Build

05 February 2026

Achieve reliable outcomes with custom aluminium fabrication by Canfred Engineering in Melbourne, supporting industrial and commercial project requirements.

Custom aluminium fabrication supports engineered projects where strength, accuracy, and long-term durability are required. Aluminium is widely used across industrial and commercial applications due to its corrosion resistance and fabrication flexibility. Reliable outcomes depend on controlled processes that convert client designs into finished assemblies without unnecessary complexity.

Design Validation and Fabrication Planning

Custom aluminium fabrication begins with a structured review of client drawings, dimensions, and functional requirements. Design intent is assessed to confirm material suitability, fabrication feasibility, and alignment with the intended operating environment. This early validation stage reduces production adjustments and supports predictable build accuracy.

Fabrication planning defines tolerances, assembly sequencing, and finish requirements before material processing begins. Clear documentation allows each stage to progress in a controlled and repeatable manner. This approach supports efficiency while maintaining consistency across the build.

Controlled Custom Aluminium Fabrication Stages That Support Build Integrity

Aluminium fabrication requires accuracy at every stage to maintain structural and dimensional consistency. Each process contributes directly to the reliability of the finished assembly:

• Material Selection: Aluminium grades are selected based on strength requirements, exposure conditions, and forming characteristics relevant to the application.

• Precision Cutting: CNC cutting produces consistent profiles and clean edges that support accurate assembly and reduced rework.

• Forming and Folding: Brake-press forming achieves controlled bends and repeatable angles without compromising material integrity.

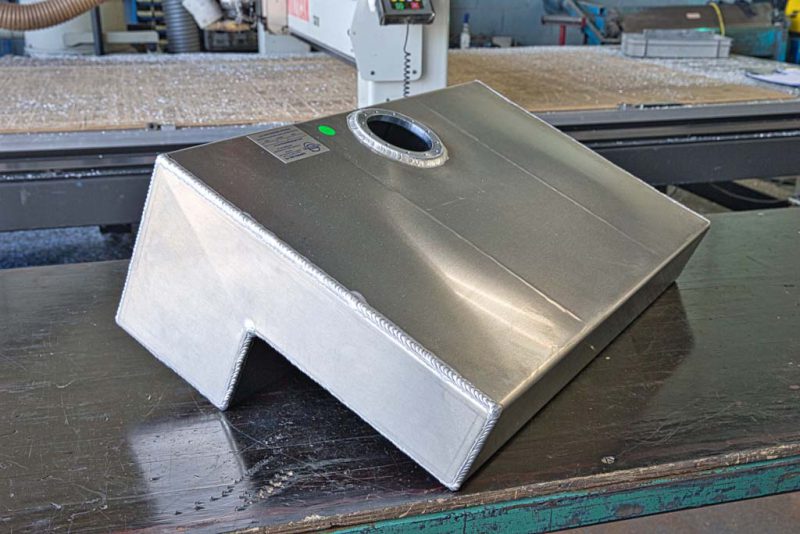

• Welding and Assembly: Qualified welding methods maintain joint strength, alignment accuracy, and structural stability.

• Surface Finishing: Finishing treatments improve durability, appearance, and resistance to environmental exposure.

For recognised Australian guidance on aluminium fabrication practices, review the Austroads ATS 5430 – Fabrication of Aluminium Components.

Inspection, Verification, and Build Completion

Custom aluminium fabrication relies on staged inspections to confirm dimensional accuracy and workmanship quality throughout production. Weld consistency, alignment, and finish condition are checked at defined points to ensure compliance with approved documentation. This verification process supports reliable performance after installation.

Final inspection confirms that completed assemblies meet specified tolerances and functional requirements. Components are prepared according to delivery or installation needs to ensure site readiness. This structured close-out supports smooth project handover without unnecessary delays.

Engineered Aluminium Outcomes Aligned with Project Requirements

Projects benefit from fabrication processes that prioritise accuracy, material behaviour, and controlled execution. Aluminium assemblies produced through disciplined workflows support consistent performance across industrial and commercial environments.

Canfred Engineering applies practical experience to custom aluminium fabrication projects that demand precision and reliability. Our work reflects a measured approach that respects design intent, material performance, and build quality from start to finish.

Contact us to discuss aluminium fabrication requirements aligned with your project scope.

Related Blog Articles:

From Drawing to Reality: How Your Designs Become Precision-Engineered Aluminium Products

Canfred: Local Aluminium Fabricators in Melbourne – 100% Australian-Made Engineering

Optimized by: Netwizard SEO